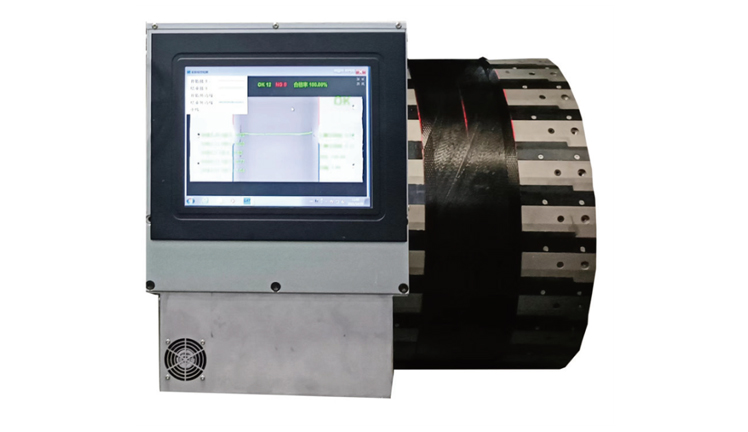

Highly Automated Operations

Our rubber tire ultrasonic cutting equipment offers highly automated operations, allowing for high-speed, continuous, and unmanned cutting processes through automated production lines. This not only improves production efficiency but also reduces labor costs and the risk of operational errors.

Environmentally Friendly

Compared to traditional mechanical cutting methods, ultrasonic cutting technology reduces environmental pollution and noise generation. It produces minimal rubber shavings and waste, while also reducing the impact of noise on the working environment and operators.

Superior Cutting Quality

Ultrasonic tire rubber cutting is characterized by fast cutting speed, high accuracy, no deformation of the rubber material, and a smooth cutting surface.

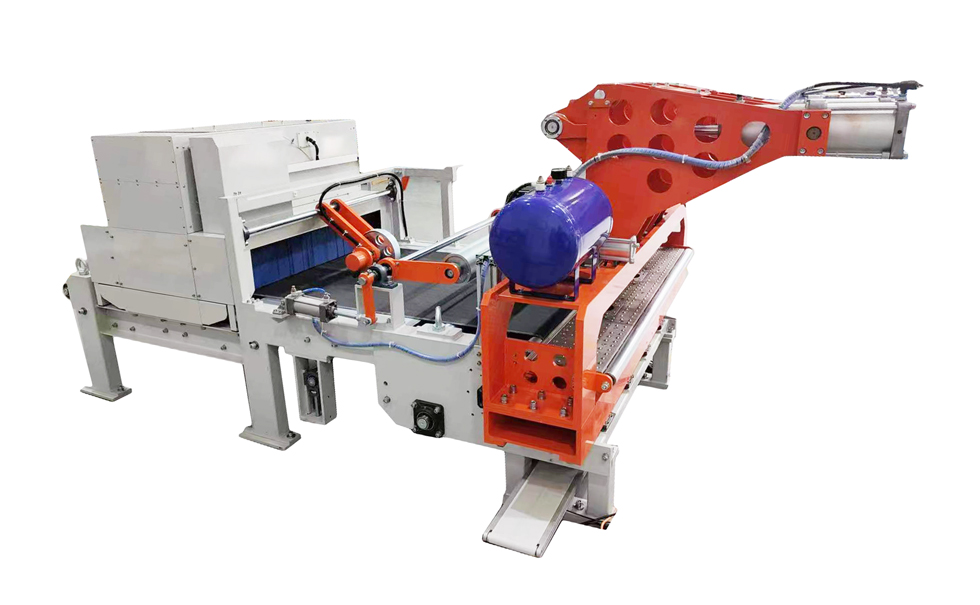

Customization Options

We offer customization and modification of non-standard projects to meet customer needs, including options such as hot knife, disc knife, double/multi-knife ultrasonic cutting, horizontal or direct cutting modification, 10-45° oblique cutting modification, and pneumatic, servo, and motor control system modification.